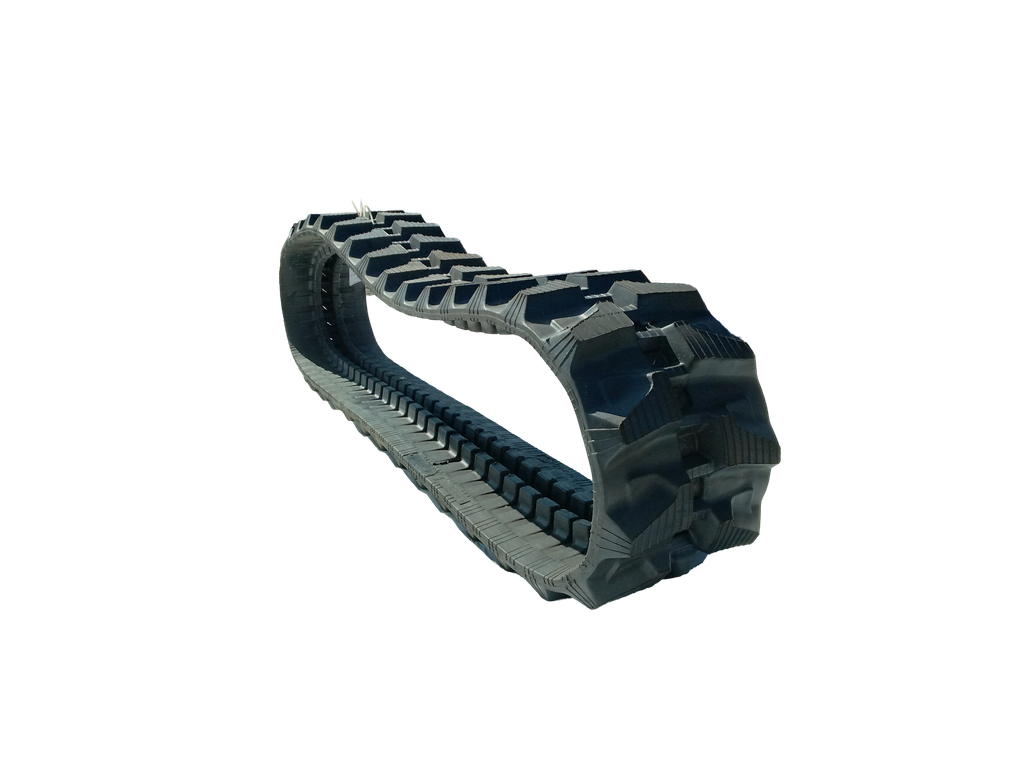

MTKS Rubber Tracks: Quality and Performance for Your Machinery

In public works, specialized machinery is key to working efficiently and safely. At Makitrucks, we offer equipment, implements, and spare parts to maintain productivity on all types of projects.

Advantages of Rubber Tracks

Rubber tracks are an essential component in heavy machinery, providing stability, traction, and durability on various types of terrain. At MTKS, we offer a wide range of rubber tracks designed to optimize the performance of excavators, mini-excavators, and other construction equipment. In this article, we’ll explore their features, benefits, and the models available in our store.

Rubber tracks offer multiple benefits compared to other traction systems:

- Greater traction and stability: They provide superior grip on uneven or slippery terrain, improving safety and machine control.

- Less damage to surfaces: They are ideal for working on paved areas without causing significant damage, making them perfect for urban and indoor projects.

- Vibration and noise reduction: They offer a smoother, quieter ride compared to steel tracks, reducing operator fatigue and improving cab comfort.

- Durability and strength: Made with high-quality materials and internal steel reinforcements, they guarantee a long service life and high performance under extreme conditions.

- Fuel efficiency: By providing a smoother, more consistent ride, rubber tracks can help reduce fuel consumption compared to metal tracks.

- Ease of maintenance: They are easier to clean and replace, minimizing machinery downtime and reducing maintenance costs.

- Greater terrain adaptability: They adapt to different surfaces, including mud, snow, sand, and gravel, without compromising the performance of the machinery.

- Lower environmental impact: Due to their lower ground pressure, they reduce soil compaction, which is beneficial for environmental preservation in sensitive areas.

- Greater operator comfort: Thanks to their shock absorption capabilities, they reduce stress on the machine and the operator, allowing for longer, more efficient workdays.

Get all our tools in our online store

Buy now!How to choose the right rubber track?

Selecting the right track for your machinery is critical to ensuring optimal performance. Here are some key factors to consider:

Size and Compatibility

Each machine requires a specific track size. Before purchasing, be sure to check the dimensions and compatibility with your equipment. At MTKS, we offer a wide catalog with different sizes. It’s also important to check the anchor type and the distance between links to ensure a perfect fit.

Terrain Type

If your equipment operates on muddy, rocky, or paved terrain, it’s important to select a track with the appropriate rubber compound to maximize its lifespan and performance. For hard, abrasive soils, a track with increased wear resistance is recommended, while for soft terrain, a model with greater flexibility and traction is preferable.

Material Quality

MTKS rubber tracks are made of high-strength materials and feature internal steel reinforcements to improve durability. Furthermore, the type of rubber used influences resistance to cuts and tears, so it’s advisable to opt for models with reinforced compounds if working in extreme conditions.

Application Type

Depending on whether you need a track for excavators, mini-excavators, or dump trucks, you’ll need to choose a model with the right features for your type of machinery. For example, tracks with a herringbone tread design provide better grip on wet terrain, while models with a smoother pattern are ideal for paved surfaces.

Traction Patterns and Tread Design

Tread pattern design influences the traction capability and stability of the machinery. Some tread patterns are designed to maximize grip in mud, snow, or gravel, while others are optimized to reduce rolling resistance and improve fuel efficiency.

Durability and Wear Resistance

Abrasion and wear resistance are important to consider. If the machinery operates in extreme conditions, such as on construction sites with sharp debris, it is advisable to choose tracks with a higher proportion of reinforced rubber and puncture protection.

Rubber Track Models at MTKS

MTKS 180x72Kx40 Rubber Track

This track is designed for mini-excavators and offers a perfect combination of strength and flexibility.

Features:

- Dimensions: 180 x 72 x 40 cm

- Compatible with various brands of machinery

- Reinforced material for greater durability

MTKS Rubber Track 230x48x68

This model is ideal for equipment such as the Takeuchi TB 216, TB 016, and TB 215R.

Features:

- Dimensions: 230 x 48 x 68 cm

- High abrasion resistance

- Optimized grip for different types of flooring

MTKS Rubber Track 350x52.5x86

Designed for models such as the Takeuchi TB 235, TB 240, TB 138, and TB 38FR, this track is an excellent choice for difficult terrain.

Features:

- Dimensions: 350 x 52.5 x 86 cm

- Longer lifespan thanks to its rubber reinforcement

- Excellent adaptation to adverse conditions

Maintenance and care of rubber tracks

To maximize the lifespan of your rubber tracks, it is important to follow some basic maintenance recommendations:

- Regular cleaning: Remove mud, stones, and debris after each workday.

- Periodic inspection: Inspect for wear, cuts, or cracks.

- Tension adjustment: Maintain proper tension to prevent premature wear.

- Avoid sharp turns: Proper use will prolong the lifespan of your tracks.

- Proper storage: If the machinery is not used for an extended period, it is recommended to store it in a clean, dry place.

Why choose MTKS for your Rubber Tracks?

At MTKS, we specialize in the sale and distribution of spare parts and accessories for construction machinery. Our commitment to quality allows us to offer long-lasting products tailored to our customers’ needs. We also guarantee:

- Fast shipping within 48-72 hours.

- Personalized technical advice.

- Permanent stock of multiple models.

- Competitive prices with the best value on the market.

Buy your Rubber Tracks on MTKS.ES

If you’re looking for high-quality, durable rubber tracks, MTKS has what you need. Visit our online store and find the perfect model for your equipment.

With over 20 years of experience in the industry, MTKS has established itself as a leader in the sale of spare parts for construction machinery. Don’t let a worn track stop your project. Trust us and optimize your equipment’s performance today.