Power, Precision, and Productivity: All About MTKS Heavy Equipment Attachments

In the world of construction, demolition, civil engineering, and industrial maintenance, heavy machinery represents a critical investment for companies. But this investment goes beyond the body of the machines: the implements they use are equally, if not more, important in ensuring efficiency, productivity, and safety in every operation. This is where MTKS, the specialized brand of Makitrucks S.L., comes into play. It stands out for its extensive catalog of high-quality implements, designed to adapt to the market’s leading brands and meet real-world needs.

Through our online platforms, makitrucks.com and mtks.es, we not only sell products and services; we also tell our story, showcase our evolution, and reinforce an identity based on professionalism, closeness, experience, and trust.

What are implements and why are they so important?

An attachment is any accessory or tool attached to heavy machinery (excavators, backhoe loaders, mini-excavators, etc.) to perform specific functions: digging, demolishing, cutting, holding, moving materials, or drilling. Without the right attachment, an excavator is nothing more than an articulated boom. Therefore, choosing the right attachment makes the difference between a productive day and a construction site at a standstill.

Analysis of the MTKS implement catalog

MTKS offers a robust and well-segmented range of implements that cover the main needs of the sector:

Our recent product unloading this week not only expands our offering; it also reinforces the type of company we are: professional, committed, and service-focused. Every piece, every implement, has been selected taking into account the real needs of our customers, using the same technical and human criteria that have guided us for more than two decades.

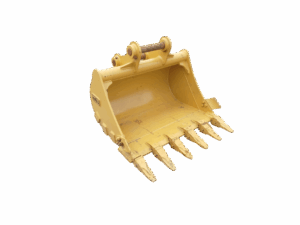

1. Reinforced buckets

Buckets are undoubtedly the most common implements. MTKS manufactures and markets reinforced buckets with high-strength HARDOX steel, specifically designed for demanding work in quarries, demolitions, earthmoving, and heavy construction.

Featured example:

MTKS Reinforced Bucket 900 mm

Ideal for excavators from 8 to 10 tons, it offers a high load capacity, tooth profile, and reinforced internal structure.

MTKS buckets stand out for their optimized design: good angle of attack, efficient material evacuation, and long service life.

2. Hydraulic hammers

MTKS hydraulic breakers are designed to withstand the most extreme impacts in demolition, trenching, or rock breaking tasks. They are easy to attach, and their vibration absorption system protects both the machine and the operator.

Featured Model:

Hydraulic Breaker for 28–40 Ton Machines

With a required oil flow of up to 320 L/min and an operating pressure of 240 bar, it delivers massive impact force without compromising machine stability.

MTKS HAMMER 1.5-2.5 TN – 170 KG

MTKS breakers are available for different weight ranges, from mini-excavators to large industrial machines.

3. Demolition and recycling tongs

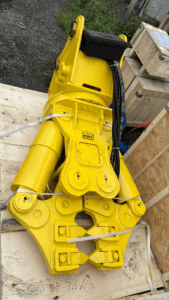

4. Quick couplers and Powertilt

Changing attachments manually can take up to 15 minutes. A hydraulic quick coupler reduces that time to seconds, allowing the operator to do so from the cab. MTKS couplers are designed to be safe, compatible, and durable.

Hydraulic coupler for Liebherr R944 LIT

Available in: MTKS Attachments

They also offer Powertilt systems, which add tilting capability to the attachment, ideal for precision work or uneven terrain.

5. Other specialized implements

- Rippers for breaking up compacted soil or ice

- Screening buckets for separating material by particle size

- Hydraulic shears for cutting industrial metal

- Compactors for settling soil in tight spaces.

Why choose MTKS attachments?

Choosing an attachment is not just a matter of price or availability. It is a strategic decision that directly affects the productivity of your site, the safety of the operator and the profitability of your machinery. MTKS stands out as one of the best options in the market, not only for its catalog, but also for the philosophy of quality, service and specialization that supports each product.

Below, we explain in detail why MTKS implements make the difference:

✔ Wide compatibility with the main brands in the market.

MTKS attachments are designed to precisely match most leading brands of machinery. This includes:

Takeuchi, Yanmar, Bobcat and Kubota, popular on mini-excavators and compact machinery.

JCB, Komatsu and Liebherr, widely used in public works.

Hyundai, Doosan and Volvo, with a strong presence in large construction sites and heavy equipment.

This mounting versatility ensures that you can easily incorporate a bucket, grapple or MTKS hydraulic breaker to your equipment, without the need to modify the structure or compromise performance. In addition, the quick coupler systems are compatible with the most common couplings on the market, both mechanical and hydraulic.

Manufacture with high-strength materials.

One of the hallmarks of MTKS is its commitment to premium materials, such as HARDOX steel, recognized worldwide for its hardness, elasticity and wear resistance. This steel, used in many buckets and structural components of the implements, multiplies the useful life compared to products manufactured with standard steel.

In addition, advanced welding techniques, structural reinforcements in critical areas and working geometries are employed that optimize performance without penalizing weight or maneuverability. This translates into:

- Less wear due to friction or impacts.

- Greater resistance in extreme conditions (rock, metal, demolition).

- Reduced medium-term costs by avoiding premature replacements.

✔ Real on-site tests: products validated by professionals.

Before being launched on the market, MTKS attachments are tested in real work situations by operators and companies in the sector. These tests make it possible to validate:

- The performance of the attachment under continuous load.

- Its resistance to impacts or intensive use.

- The ease of assembly, coupling and maintenance.

Thanks to this process, MTKS does not only sell attachments “that should work”, but products that have already proven to work, even in the most demanding conditions. This philosophy reduces risks for the customer and reinforces confidence in the brand.

✔ Fast delivery and immediate availability

One of the big problems in the industry is the lack of stock and long lead times that can paralyze projects. MTKS is committed to real availability:

Most demanded implements in permanent stock.

Shipping in 24 to 72 hours to any point of the peninsula.

Immediate pick up in our physical store in A Coruña.

Reinforced packaging and own logistics to guarantee the optimal state of the product.

This service allows us to react quickly to unforeseen events (a breakage, a work that changes planning, a new urgent contract), without compromising quality or support.

✔ Personalized technical advice and after-sales support.

Not all jobs require the same attachment, and it is often unclear which one is the most suitable for a particular machine. MTKS knows this, which is why it offers specialized technical support for both large companies and freelancers.

The MTKS technical team will help you:

- Choose the compatible attachment according to make, model, tonnage and hitch type.

- Determine the optimal size, weight and geometry.

- Calculate the expected performance in specific tasks (such as demolition, aggregate movement, recycling…).

- Configure quick hitch or powertilt systems according to your needs.

In addition, they offer after-sales support, including spare parts, basic maintenance and solution of technical doubts once the attachment is installed.

✔ Brand with local roots and industrial vision.

MTKS is not a distant multinational: it is a brand developed in Galicia, from direct knowledge of the real needs of local construction, public works, demolition, forestry and logistics companies.

This means that its products:

- Are designed for real terrain (rock, mud, water, harsh climates).

- Are tested in real conditions, not just in the lab.

- They are designed from the experience accumulated over the years with customers and worksites in Galicia, Asturias, Leon and northern Portugal.

How to get the most out of your MTKS implements

Investing in quality implements such as those offered by MTKS is a smart decision that can significantly increase the performance of your machinery. However, to take advantage of their full potential, it is essential to accompany this investment with good operating and maintenance practices.

Here is a guide with key recommendations to extend the life of your equipment, improve its efficiency and protect your investment in the long term:

Perform regular check-ups and preventive maintenance.

Although MTKS implements are manufactured with high-strength materials such as HARDOX steel, all parts subjected to intensive work require regular maintenance. Establishing a technical revision protocol every certain number of hours of use is essential to prevent major breakdowns.

At each overhaul, the following should be checked:

- Structural welds and joints: to avoid invisible cracks that can lead to breakage.

- Hydraulic system: check hoses, connections, pressure and tightness.

- Teeth, blades or wear elements: replace them before they are completely deteriorated to avoid damage to the implement body.

- Greasing of moving points: especially on grapples, hammers and quick hitches, to ensure smooth and long-lasting movement.

A preventive overhaul can save you days of machine downtime and hundreds or thousands of euros in repairs.

Always use the right attachment for the task.

Each attachment is designed with a specific function and defined limits of use. Using an attachment outside these limits reduces its service life and can cause damage to the machine.

- Don’t use a light hydraulic breaker to break solid rock; that’s what heavy-duty models are for.

- Don’t overload a small bucket with heavy materials such as stone or steel, which are designed for smaller volumes.

- Don’t use a demolition grapple to move dirt or debris if it’s not set up for it.

Using the right attachment for the right task ensures greater efficiency, lower fuel consumption and less stress on the machine.

- Train the operator in the proper use of the implement.

A poorly used implement can perform half its capacity or even suffer irreversible damage in a short time. Operator training is as important as the quality of the equipment.

Make sure your staff knows:

- How to properly assemble and disassemble attachments.

- What functions and limitations each tool has.

What signs of wear or malfunction to watch for. - What to do in case of noise, vibrations or leaks.

At MTKS, the technical team can help you train your personnel or give you guidelines to integrate this training into your safety protocol.

- Use quick hitches and powertilt for increased versatility.

Hydraulic quick hitches and powertilt systems allow you to change attachments in seconds, without getting out of the vehicle, and work with slope angles on uneven terrain or in hard-to-reach areas.

These tools:

- Increase the productivity of each machine.

- Reduce downtime between tasks.

- Eliminate the risk of manual tool changes.

- Allow a single machine to take on several functions on site, reducing the number of units required.

You can consult the complete catalog of MTKS couplings here:

✅ Always buy from a supplier with technical support and warranty, such as MTKS.

Purchasing an implement should not be limited to the commercial transaction. Ideally, you should have a supplier that understands your business, your machine and your goals. MTKS offers:

- Quality guarantee on all its implements.

- Personalized advice to choose the right model.

- Clear and complete technical data sheets for each product.

- After-sales service and stock of spare parts to extend the useful life of the equipment.

- Immediate attention in case of any doubt, problem or need for extension.

This allows you to operate safely, solve any incident quickly and be sure that you are investing your money well.

Customer feedback

Where to buy MTKS implements?

You can view the entire catalog, consult technical data sheets, place orders or request advice in their online store:

🔗 mtks.es

📍 Or visit their headquarters at:

Av. Pasaxe 89, 15006 A Coruña.

📧 comercial@mtks.es

📞 981 13 13 27