How to Choose the Ideal Ramp for Your Construction Machinery

On any construction site, loading and unloading heavy machinery is a routine task that requires safety, precision, and the right equipment. Among all these tools, ramps play a fundamental role: they are the bridge that ensures excavators, dumpers, or skid steer loaders can move safely between the ground and the truck or trailer. Choosing the right ramp not only prevents accidents and breakdowns, but also improves productivity and protects your investment in machinery.

When working in construction, safety and efficiency in loading and unloading processes are just as important as the performance of the machinery itself. Loading or unloading heavy equipment—whether it’s a mini excavator, a dumper, a skid steer loader, or a backhoe—requires one essential accessory: the right ramp.

Choosing the wrong one can lead to accidents, equipment damage, project delays, and unnecessary expenses. That’s why in this article, I’ll explain in detail the different types of ramps, how to choose the best one for your case, and the most common mistakes to avoid.

Types of Ramps for Construction Machinery

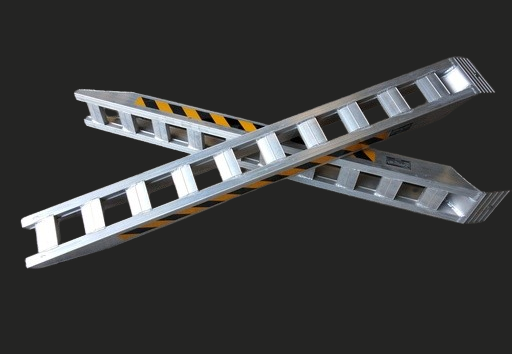

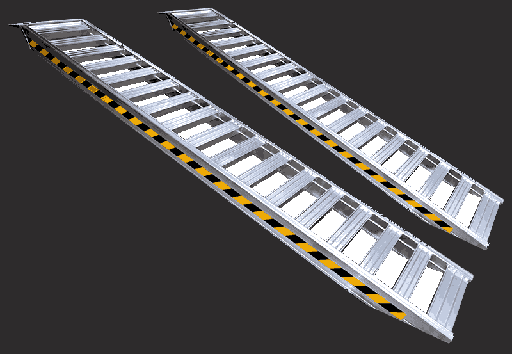

- Aluminum ramps

The most widely used in the industry because they combine strength and lightness. Their low weight allows a single worker to handle them without difficulty. Despite that, they can support heavy loads, making them perfect for mini excavators, dumpers, or aerial platforms. They also come in multiple lengths and widths, offering great versatility.

- Steel ramps

Heavier than aluminum but also more robust. They are recommended when frequently handling very heavy machinery, as they can withstand higher wear and tear. They are less practical for transport but sometimes more cost-effective.

- Folding and telescopic ramps

Ideal for those who need to transport them in smaller vehicles or with limited storage space. Their design makes them easy to store, although they generally have a lower load capacity compared to fixed ramps.

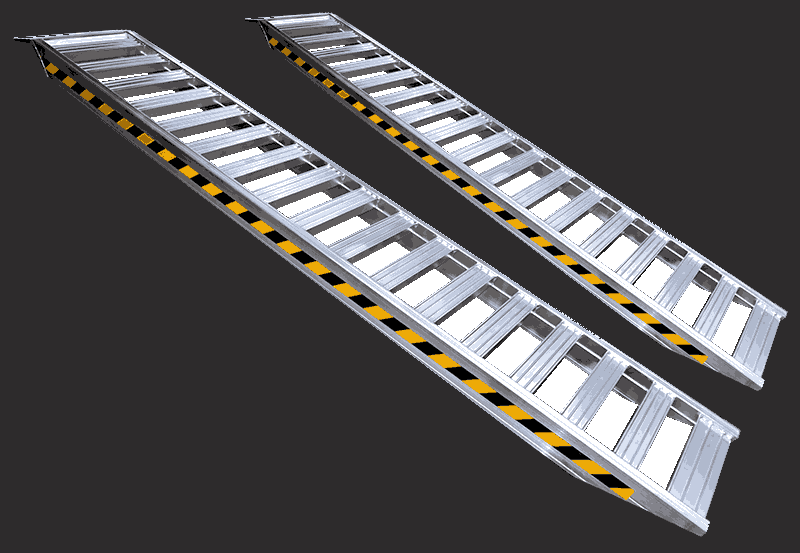

- Ramps with safety edges

These include raised sides that act as guides, preventing the machine from slipping off accidentally. They are an excellent option for less experienced operators or in low-visibility environments.

- Ramps designed for tracked machinery

These usually feature reinforced anti-slip surfaces, improving traction for rubber or steel tracks and increasing the ramp’s durability against wear.

Ramps for heavy machinery for sale

Buy now!Key Factors for Choosing the Right Ramp

Choosing a ramp is not only about price or material. Several aspects need to be evaluated:

- Load capacity

The ramp must withstand the weight of the machine, the operator, and any accessories. Don’t just match the load limit to the machine’s weight—always apply a 25–30% safety margin.

- Length

The length determines the climbing angle. The longer the ramp, the gentler the slope and the safer the maneuver.

- Low trucks: 2.5–3 m.

- Medium trucks: 3–3.5 m.

- High trailers or semi-trailers: 4 m or more.

- Type of machinery

- Wheeled machinery: standard ramps with anti-slip surfaces are enough.

- Tracked machinery: reinforced surfaces are recommended for extra traction and durability.

- Frequency of use

If used only occasionally, a basic model may be sufficient. For daily or intensive use, it is better to invest in high-quality ramps made from durable materials.

- Width

It must match the distance between the wheels or tracks of the machine. Many ramps are sold in pairs, which makes them adaptable to different widths.

- Fixation system

It is essential that ramps include a reliable anchoring system (hooks, lugs, or supports) to ensure they don’t move during use.

Common Mistakes When Choosing or Using Ramps

Although it may seem simple, many accidents and breakdowns happen because of poor ramp choice or misuse. The most frequent mistakes are:

- Not calculating the real load: using ramps that don’t support the total weight can cause bending or breakage.

- Choosing ramps that are too short: a steep slope increases the risk of sliding or tipping over.

- Failing to secure the ramps: using ramps without proper fixation is a critical safety error.

- Ignoring the condition of the ramps: cracks, deformations, or worn anti-slip surfaces can easily cause accidents.

- Using the wrong type for tracks: steel tracks can damage ramps that aren’t reinforced.

Practical Tips for Choosing and Maintaining Your Ramps

- Think about the most frequent use: if you work with different types of machines, you may need more than one ramp type.

- Ensure they are easy to transport: ramps that are too heavy will make daily work harder.

- Invest in safety: ramps are not an expense but an investment to protect operators and equipment.

- Clean and inspect regularly: mud, oil, or gravel can reduce traction and increase the risk of slipping.

Store ramps in a dry place: even aluminum or treated steel will last longer if kept away from humidity.

Choosing a ramp for construction machinery should not be taken lightly. It is a critical safety component that directly impacts worksite productivity and protects both machines and operators.

Understanding the different types, analyzing key factors such as load capacity, length, width, surface type, and fixation systems, while avoiding the most common mistakes, are all essential steps in making the right decision.

In short, the ideal ramp will be the one that adapts to your machinery, your work style, and your construction environment, ensuring efficiency, safety, and durability.

How to Choose the Ideal Ramp for Your Construction Machinery

Practical guide to selecting loading ramps for mini excavators, dumpers, skid steer loaders, and backhoes. We compare aluminum vs. steel, folding/telescopic options, safety edges, and reinforced surfaces for tracks, with criteria such as load capacity, length, width, and fixation systems.

Types of Ramps

- Aluminum: high strength-to-weight ratio, wide range of lengths and widths.

- Steel: greater robustness and durability for intensive use and very heavy loads.

- Folding and telescopic: easy to transport and store; lower capacity than fixed models.

- With safety edges: guide the wheels and reduce the risk of sliding off the sides.

- For tracks: reinforced anti-slip surfaces for traction and reduced wear.

Key Selection Factors

- Load capacity: machine weight + operator + accessories, with a 25–30% safety margin.

- Length: defines the slope. Low truck 2.5–3 m; medium truck 3–3.5 m; high semi-trailer ≥4 m.

- Width: must match the distance between wheels or tracks; many ramps are sold in pairs.

- Usage and frequency: occasional (basic model) vs. intensive (premium materials).

- Fixation: hooks, lugs, or supports to prevent shifting during use.

Common Mistakes

- Not calculating the actual weight and exceeding the permissible load.

- Choosing ramps that are too short, increasing slope and risk of sliding or tipping over.

- Not securing the ramps to the vehicle/platform.

- Ignoring cracks, deformations, or worn anti-slip surfaces.

- Using non-reinforced ramps with steel tracks.

Maintenance and Safety

- Regular inspection and cleaning (mud, oil, and gravel reduce traction).

- Store in a dry place to extend the life of aluminum and treated steel.

- Invest in quality fixation systems and anti-slip surfaces.

Need help sizing your ramp? Check our MTKS Ramps category or contact us for technical advice and transport.